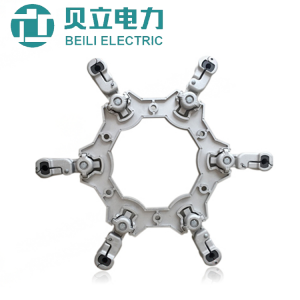

JJE Series C Type Equipment Clamp

Description:

The C-type equipment clamp is composed of a tailed C-piece hinge block and bolt parts, which make use of the continuity of equipment and wires. According to GB / T1196 standard, it is prepared from a special alloy gold-conducting electrical material. It is coated with anti-corrosion / anti-oxidation / hydrophobic and highly conductive power compound grease, which can make good conductive contact of different materials

The overall extrusion molding of the C-type equipment clamp is proportional to the traditional equipment clamp, which can solve the problem of easy fracture / corrosion / easy heating of the copper famous product welding position. The advanced hinged structure is very labor-saving and greatly reduces labor intensity Improve work efficiency (different directions of force and pressure, greatly reduce the impact of human factors during installation)

installation:

Composition of C-type equipment installation clamps: type housing, hinge block, square block, stainless steel screw, hot-dip galvanized nut, stainless steel spring washer, stainless steel washer

1. Determine the model: According to the specifications of the conductor, find the corresponding conductor model in the C-type energy-saving equipment clamp selection table. The main line is used as the abscissa axis, the branch line is used as the ordinate axis, and the position where the two coordinate axes intersect is C The model of the energy-saving equipment line is the type of this connection (note the selection of different specifications of materials)

2. Determine the size of the wire: because the C-clamp is designed to meet the requirements of different wire diameters, the arc surfaces on both sides of the hinge block have different sizes, the large arc surface matches the large wire, and the small arc surface matches the small wire.

3. Put the wire into the C-type housing wire groove: According to the size of the wire into the arched hinge block (the hinge block does not separate the bow-shaped outward) insert the screw from the back of the C-type housing, so that the screw is located on the top of the hinge block In the middle hole, tighten the nut with a wrench to tighten the bolt, and flatten the wire

4. Make sure that it is installed: When tightening the bolts, the last few teeth should have a clear sense of force, flatten the hinge block and hold the C-type housing. At this time, the C-type housing should be slightly deformed. After the installation is completed, pull the two wires by hand. At this time, the wires are fully moved before they are compressed.

|

Model |

Single Wire Specification |

|

SP-S11-1 |

LGJ240 |

|

SP-S12-1 |

LGJ185、LJ(TJ)240、JKLYJ240 |

|

SP-S21-1 |

LGJ150、LJ(TJ)185、JKLYJ185 |

|

SP-S32-1 |

LGJ120、LJ(TJ)120、LJ(TJ)150、JKLYJ150 |

|

SP-S42-1 |

LGJ95、LJ(TJ)95、JKLYJ120 |

|

SP-S51-1 |

LGJ70、JKLYJ95 |

|

SP-S53-1 |

LGJ50、LJ(TJ)70、JKLYJ50 |

|

SP-S61-1 |

LGJ35、LJ(TJ)35,50、JKLYJ50 |

|

SP-S62-1 |

LJ(TJ)25、JKLYJ35 |

|

Model |

Suitable for Double Wire Specification |

|

SP-S11 |

LGJ204 to LGJ240、 |

|

SP-S12 |

LJ(TJ)240 to LJ(TJ)240 |

|

SP-S13 |

LJ(TJ)240 to JKLYJ240、 |

|

SP-S14 |

LJ(TJ)240 to LJ(TJ)240 to JKLYJ185、 |

|

SP-S15 |

LJ(TJ)240 to LJ(TJ)120,95、 |

|

SP-S16 |

LJ(TJ)240 to LJ(TJ)70,50,35、 |

|

SP-S21 |

LJ(TJ)185 to LJ(TJ)185、 |

|

SP-S22 |

LJ(TJ)185 to LJ(TJ)150,120、 |

|

SP-S23 |

LJ(TJ)185 to LJ(TJ)95,70、 |

|

SP-S24 |

LJ(TJ)185 to LJ(TJ)50,35、 |

|

SP-S31 |

LGJ150 to LGJ150 |

|

SP-S32 |

LJ(TJ)150 to LJ(TJ)150 |

|

SP-S33 |

LGJ150 to LGJ70、 |

|

SP-S34 |

LGJ180 to LGJ25、 |

|

SP-S41 |

LGJ150 to LGJ120、 |

|

SP-S42 |

JKLYJ150 to JKLYJ120、 |

|

SP-S43 |

LJ(TJ)150 to LJ(TJ)70,80、 |

|

SP-S44 |

LJ(TJ)150 to LJ(TJ)35、 |

|

SP-S45 |

LJ(TJ)120 to LJ(TJ)25,16、 |

|

SP-S51 |

LJ(TJ)95 to LJ(TJ)70、 |

|

SP-S52 |

LJ(TJ)70 to LJ(TJ)70、 |

|

SP-S54 |

LJ(TJ)70 to LJ(TJ)50、35 |

|

SP-S61 |

LJ(TJ)70 to LJ(TJ)25,16、 |

|

SP-S62 |

LJ(TJ)50,35 to LJ(TJ)50,35、 |

|

SP-S63 |

LJ(TJ)50 to LJ(TJ)25,16、 |

|

|

LJ(TJ)16 to LJ(TJ)16、 |