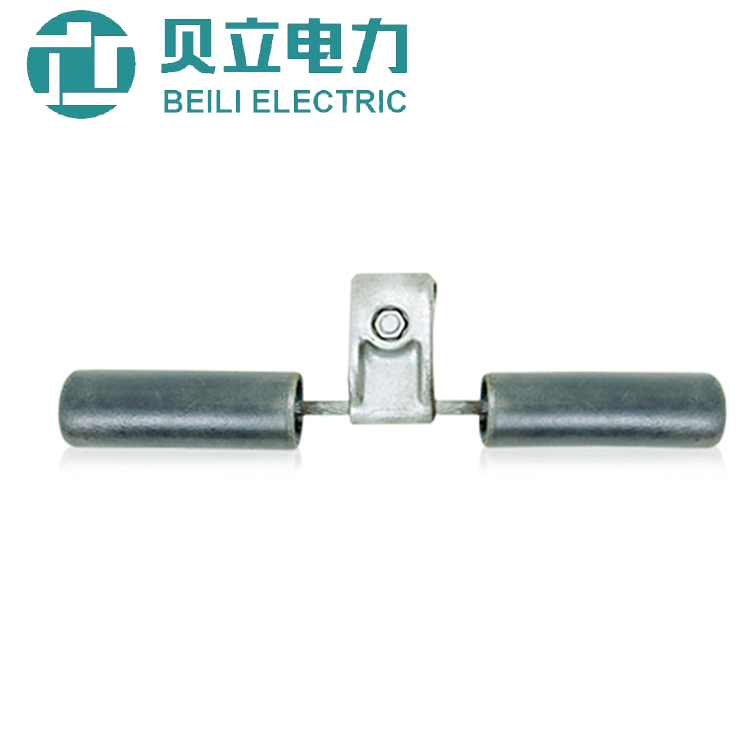

FD-L Anti-Vibration Damper

Description:

The preformed anti-vibration damper uses preformed wire as the connection structure of the anti-vibration vertical clamp and the protected wire, so it has a preformed metal fitting that is easy and quick to install and has good digging force on the wire (avoiding the clamp caused by thermal expansion and contraction) Looseness), even digging force does not hurt the wire, no hidden danger of bolt loosening (maintenance-free), good anti-halo, energy saving (pre-stranded wire and clamp are made of aluminum alloy), superior fatigue resistance and other advantages.

Features:

1.Pre-stranded wire for aluminum clad steel installation

2.Easy installation (no tools required)

3.Safe and reliable (no damage to wires)

4.Maintenance-free (no loose bolts)

5.Low installation costs (only ten seconds to install a product)

6.Easy and reliable acceptance and observation

Comparison of preformed anti-vibration damper and traditional bolted anti-vibration damper:

Traditional anti-vibration tanks are fixed by bolts. During installation, construction workers must be equipped with torque wrenches. Once the construction team does not have these tools, excessive or small torque will occur. Excessive torque may cause damage to the wires or bolts; if the torque is small, the digging force between the anti-vibration damper and the wires cannot meet the standard.

The preformed anti-vibration damper eliminates the disadvantages of the bolted anti-vibration damper described above. The installation of the preformed anti-vibration damper can be completed with bare hands without the need for a task tool, the installation is convenient and quick, and the construction cost is low.

The grip between the preformed wire and the guide of the anti-vibration damper is evenly distributed over a length of 30 to 60 mm, which avoids the stress concentration of the wire.

In addition, the installation quality of the preformed anti-vibration damper can be observed and judged on the ground with a telescope, which greatly reduces the difficulty and cost of project acceptance and greatly improves the reliability of acceptance.

In summary, the advantages of the preformed anti-vibration damper can be summarized as follows:

1. Easy installation and low installation cost;

2. Safe and reliable, maintenance-free;

3. High construction efficiency, convenient and reliable acceptance.

|

Type |

Applicable Stranded Wire Section Area |

Dimension |

Wire Size |

Weight |

||||

|

D |

A |

H |

L1 |

L |

||||

|

FD-1L |

35-50 |

40 |

50 |

81 |

95 |

300 |

7/2.6 |

1.5 |

|

FD-2L |

70-95 |

46 |

50 |

81 |

130 |

370 |

7/3.0 |

2.4 |

|

FD-3L |

120-150 |

56 |

50 |

81 |

150 |

450 |

19/2.2 |

4.5 |

|

FD-4L |

185-240 |

62 |

50 |

91 |

175 |

500 |

19/2.2 |

5.6 |

|

FD-5L |

300-500 |

67 |

50 |

96 |

200 |

550 |

19/2.6 |

7.2 |

|

FD-6L |

500-630 |

70 |

50 |

96 |

200 |

550 |

19/2.6 |

8.6 |

|

1. The hammer head is gray iron casting and lacquering, and the rest is hot-dip galvanized steel. The hammer head and steel strand are connected by riveting. |

||||||||